Steel Frame Designs for Commercial Structures

08 Sept 22 Shane Barker, Business Development Manager

Steelcorp’s commercial and industrial structures are designed with several different frame options depending on the purpose and style of the building.

The most common types of frames we use are:

- RHS frames

- UB frames

- Web truss

In this article, Shane covers the different frame options, and how our design team works with you to find the best design for your steel structure.

CONTENTS

Steel Frame Designs for Commercial Buildings

IN BRIEF

- RHS is popular for structural projects, but it’s expensive and not suitable for spans over 15m or buildings higher than 5m.

- Universal Beams (UB) are a more suitable material for most of our commercial projects, but again, can be expensive due to the weight of steel involved.

- Web trusses can be a solution to lighten the structure and decrease the material cost whilst maintaining strength.

- Engaging a structural engineer early in your project will ensure you get a good balance of strength and cost-efficiency.

RHS Frames

Rectangular Hollow Section (RHS) is a popular material for structural projects. This flat, prefabricated rectangular steel is available in a range of different sizes and thicknesses, with the thicker variants being more rigid and suitable for heavy-duty applications.

RHS is typically ordered in standard lengths and then cut to size during the fabrication process, making it a strong and versatile material. It also doesn’t require much edge preparation for welding making it easy to work with during the production process.

However, there are some drawbacks to RHS: it is more expensive per tonne and is not suitable for the kind of larger structures that Steelcorp typically designs.

Rectangular hollow section is really only suitable for spans under 15m and building heights under 5m, which means it is not the best choice for most commercial projects.

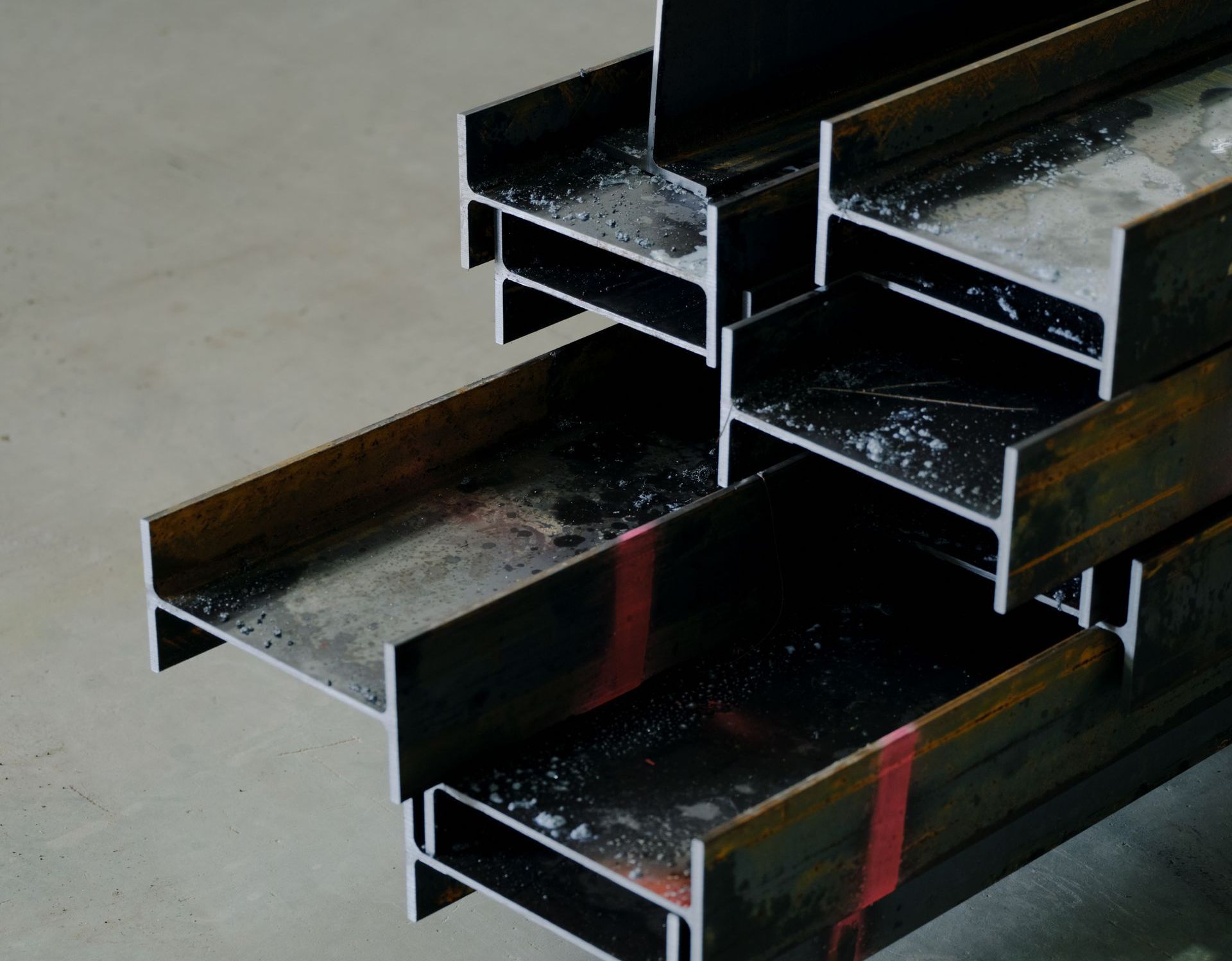

Universal Beams

Universal beams (UB) are also known as I Beams, H Beams or RSJ. These structural steel members are manufactured using a hot rolling process which strengthens the steel, making it well suited to critical sections of the structure such as main portal frames and rafters.

Available in 5mm up to 20mm thick options, structural steel is a must for applications where heavy machinery is involved, or strong roof support is needed, for example, if a gantry crane will be used inside the structure.

"Structures made completely out of universal beams can be inefficient and very expensive due to the increased tonnage, but we can design full UB structures if the project requires it."

- Shane Barker, Steelcorp

Web Truss Frames

Web truss frames are made from RHS & SHS sections: a network of structural steel creating an open roof skeleton that is intrinsically strong.

The triangular design of web trusses distributes the weight of the roof evenly and transfers load down into the walls and foundations.

It also allows for better connections at the knee joint (where the columns meet the truss) – these good connections are critical to the structural integrity of a building.

How a Structure Comes Together at Steelcorp

Although we design customised structures for every project, we typically start with our signature ‘Steelcorp frame’.

This design is engineered using hot dip galvanised universal beam columns and web truss rafters, providing an excellent balance of strength and cost efficiency. This type of frame is ideal for spans from 18m up to 60m and has been proven across many projects.

Get a Strong and Cost Effective Structure with Steelcorp

Steelcorp’s building designs are structurally engineered to deliver the right balance of strength and cost efficiency.

An Australian Made Steelcorp structure will provide you with the durability, design freedom and strength necessary for your commercial building. Give our friendly team a call for advice or to chat with us about your project.

Subscribe to our newsletter

Thank you.

Please try again later.

CONNECT

WEBSITE

© STEELCORP 2023